TAILORED TO ANY SIZE

LSM has the expertise and capability to manufacture camshafts over 2.5 meters long, either as single pieces or assembled from multiple segments. With experience in producing large camshafts for generators, locomotives, and military applications, LSM can handle the assembly process and produce connector segments, shipping fully completed camshafts to meet diverse requirements.

SERVING ALL INDUSTRIES

At LSM Systems Engineering, our prototyping capabilities span industries. For over 30 years, we have helped our customers in the automotive, rail, marine, and other industries bring their ideas to life with prototypes. As innovators in engineering, we are open to expanding our horizons, so we invite customers from all sectors to share their ideas with us.

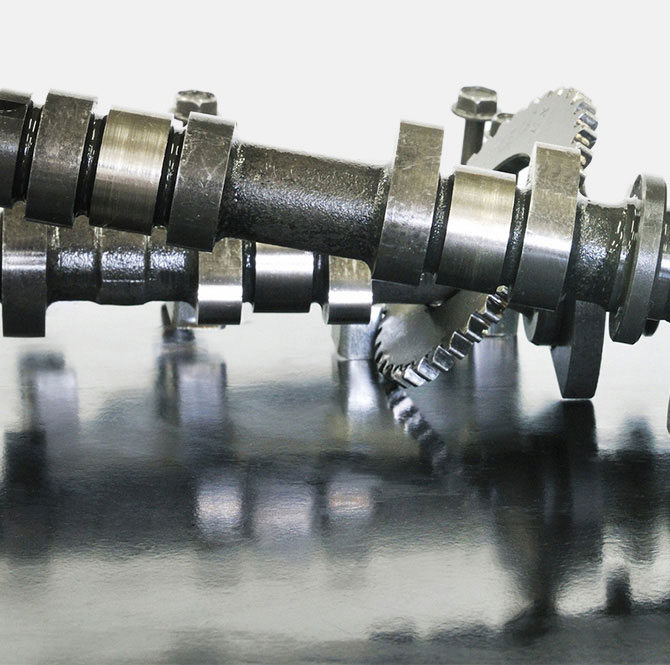

CAMSHAFT MANUFACTURING

When you are ready to move past the prototype phase, LSM Systems Engineering has the ability to manufacture camshafts of all kinds. We can manufacture custom camshafts to fit any application, from large to small.

CUSTOM CAM CORES

LSM can produce cores for your prototype application. Cores, also known as UGLs, are produced so that you can select the final grind profile at a later date. This allows for quick testing of a variety of profiles. We take a quality-controlled approach to manufacturing cores by precisely locating each feature.

Why Customers Choose LSM

Learn why many customers choose LSM for their camshaft projects. LSM is fully certified for production manufacturing and has the capabilities to do the advanced machining needed to support your project.

Bring Your Ideas to Life with Our Prototypes

Ready to get started on your prototype cam project? Reach out to our team of experts today to discuss your needs and timelines. Let us show you why we’re the trusted choice for specialty cams in the industry. We can often produce expedited cams in under 6 weeks if your project demands the fastest turnaround time.