ANY SIZE YOU NEED

LSM specializes in manufacturing camshafts over 2.5 meters long, whether as a single piece or assembled from multiple segments. With extensive experience in producing large camshafts for generators, locomotives, and military applications, we are equipped to manage every aspect of the process, including the manufacture of connector segments and the assembly of completed camshafts. Our comprehensive capabilities allow us to deliver fully assembled camshafts tailored to meet the specific needs of our customers.

WE SERVE ALL INDUSTRIES

For over three decades, LSM Systems Engineering has provided camshaft production services to customers across a wide range of sectors. We understand the unique needs that certain industries have and how to best meet them with our customized solutions. Our team’s focus is on the automotive, marine, military, and rail industries.

PROTOTYPE CAMSHAFTS

LSM is your ideal partner if you are working on a new camshaft and need prototypes for testing before launching production. Let us make your prototypes so you will have cams to test quickly then easily transition into production. It’s just one way that we exemplify our deep commitment to our customers’ success.

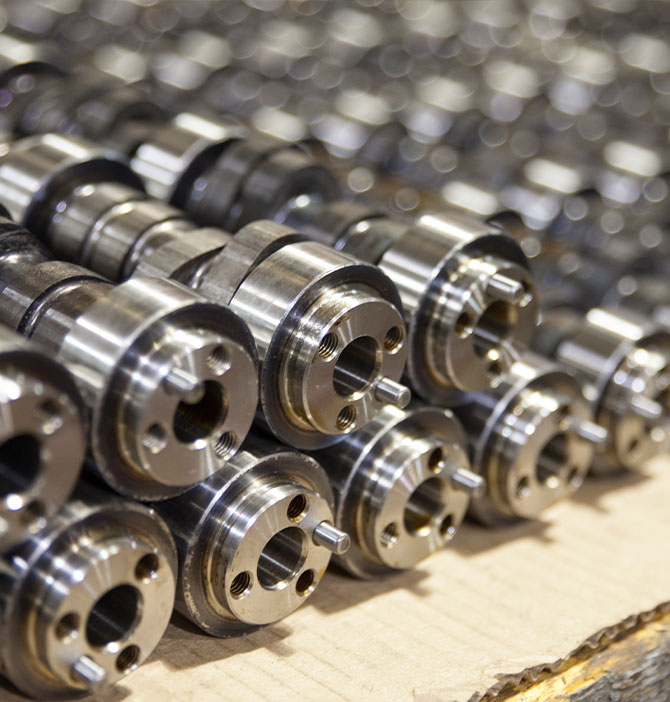

CUSTOM CAM CORES

Along with fully finished camshafts, LSM can produce cam cores, also known as UGLs, for any application. Taking a quality-controlled approach to manufacturing cam cores, we precisely locate each feature. We can produce a production run of cam cores that you can have us grind to customized specifications at a later date or you can take to have ground yourself.

Why Customers Choose LSM

Learn why many customers choose LSM for their camshaft projects. LSM is fully certified for production manufacturing and has the capabilities to do the advanced machining needed to support your project.

Move Into the Production Stage

When you are ready to move into the production stage of your camshaft project, LSM Systems Engineering can help you. Working from your specifications, we can produce camshafts of any size or shape. To learn more about our production process or request a quote, contact our team today. We look forward to partnering with you.