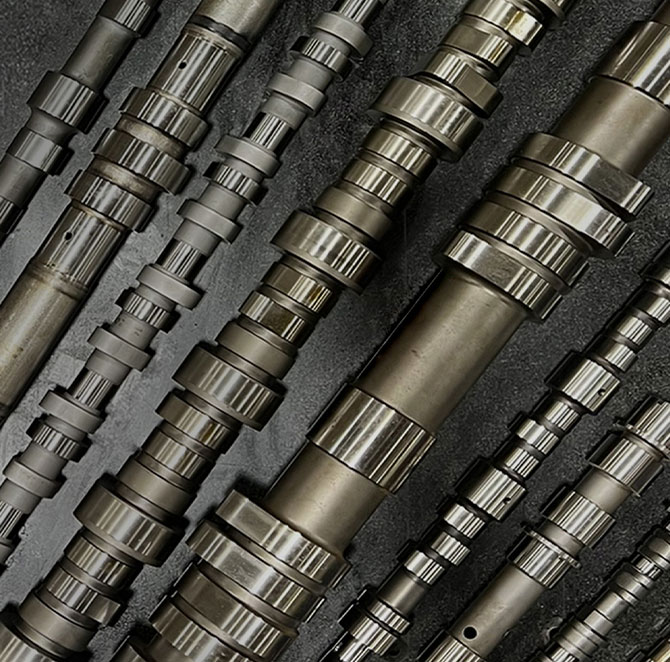

CUSTOM LARGE CAMSHAFTS

LSM has the capability to manufacture camshafts over 2.5 meters long, either as a single piece or assembled from multiple segments. With experience serving the generator, locomotive, and military industries, we manage everything from manufacturing cam segments to final assembly, delivering completed camshafts tailored to our customers' specific requirements.

TAILORED TO ANY INDUSTRY

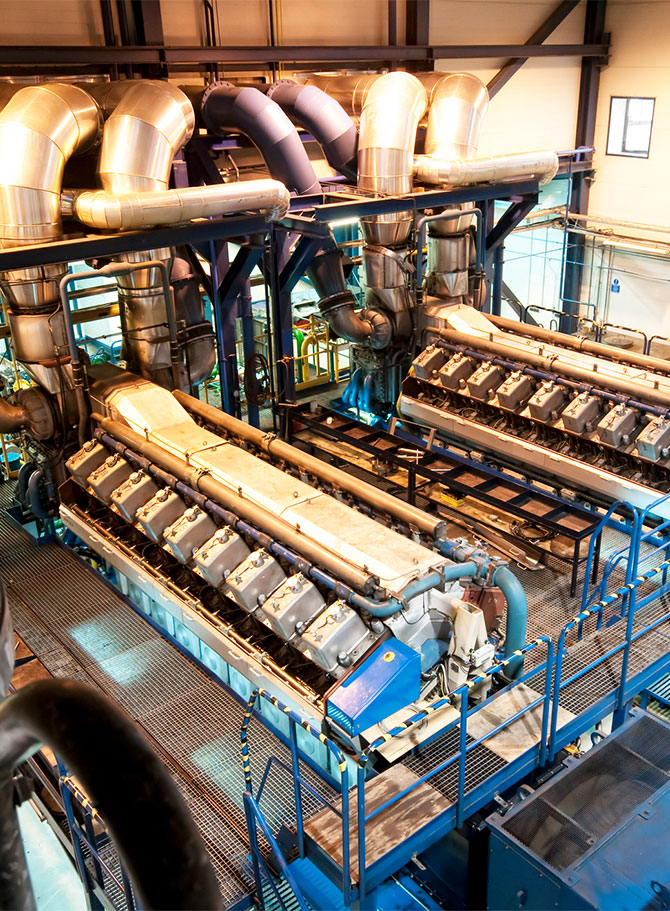

Large camshafts are ideal for large engines used in industrial and heavy-duty applications. LSM Systems Engineering has over 30 years of experience working with heavy equipment, particularly in the marine, rail and generator industries.

PROTOTYPE CAMS FOR LARGE ENGINES

LSM can help when you have a new large cam application and are in need of a prototype. We have manufactured numerous cams for testing and process development for new large engines before going into production.

LARGE CUSTOM CAM CORES

LSM can manufacture large unground lobe camshafts (UGLs) for your application. These cores can accommodate a variety of finished profiles and are ideal for testing your large engine concept.

Why Customers Choose LSM

Learn why many customers choose LSM for their camshaft projects. LSM is fully certified for production manufacturing and has the capabilities to do the advanced machining needed to support your project.

Experience the Service You Require

With LSM producing your large camshafts you will know that your camshafts are processed properly and that we pay attention to the details needed for your camshaft to succeed. When you’re ready to start your large camshaft project please reach out to us so we can get started.