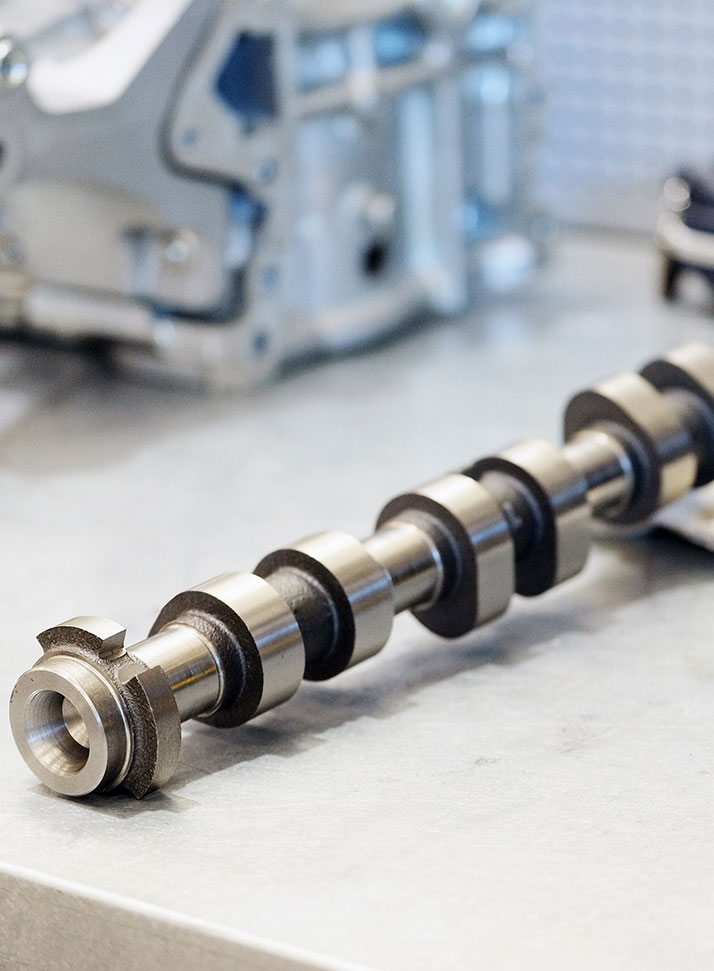

CAMSHAFTS IN ANY SIZE

LSM is an experienced camshaft manufacturer making large cams for generators, locomotives and the military. Many of these larger cams need to be assembled. We can make the connector segments and ship completed cams.

CAMSHAFTS FOR ALL INDUSTRIES

For over 30 years, LSM Systems Engineering has provided custom camshafts to customers in a wide range of industries. We understand the needs of specific applications, such as those required by the military, marine, rail, and automotive industries, among others. We can meet and exceed any industry’s standards.

PROTOTYPE CAMS

We understand that your prototype camshaft is a work in progress. We can make prototypes to your specifications and can review your design for manufacturability. Prototypes can be provided with full source inspection data.

CUSTOM CAM CORES

A cam core is a camshaft that is complete except for the cam lobes. Customers can take these cores (also known as Unground Lobe/UGL cams) and grind a variety of finish grinds. We produce cam cores for customers interested in customizing their own grinds.

Why Customers Choose LSM

Learn why many customers choose LSM for their camshaft projects. LSM is fully certified for production manufacturing and has the capabilities to do the advanced machining needed to support your project.

Request a Quote for Your Custom Camshaft

No matter what kind of camshaft you need for your application, LSM can create it. We leverage 30 years of experience along with the latest manufacturing tools to ensure that you get the camshaft that you need. To request a quote on your project, click on one of the buttons below.