Our Delivery

Our goal is to deliver your parts when you need them. We typically can provide a new part within 20-24 weeks and can expedite parts when requested. We consistently maintain on-time-delivery performance of greater than 95% on all orders and 100% on those with promised delivery dates.

About Our Quality

LSM is ISO 9001:2015 and IATF 16949:2016 certified, and we strive to maintain our near-perfect quality record. LSM Systems Engineering is committed to providing an amazing customer experience by producing critical components that meet all customer requirements with on-time delivery.

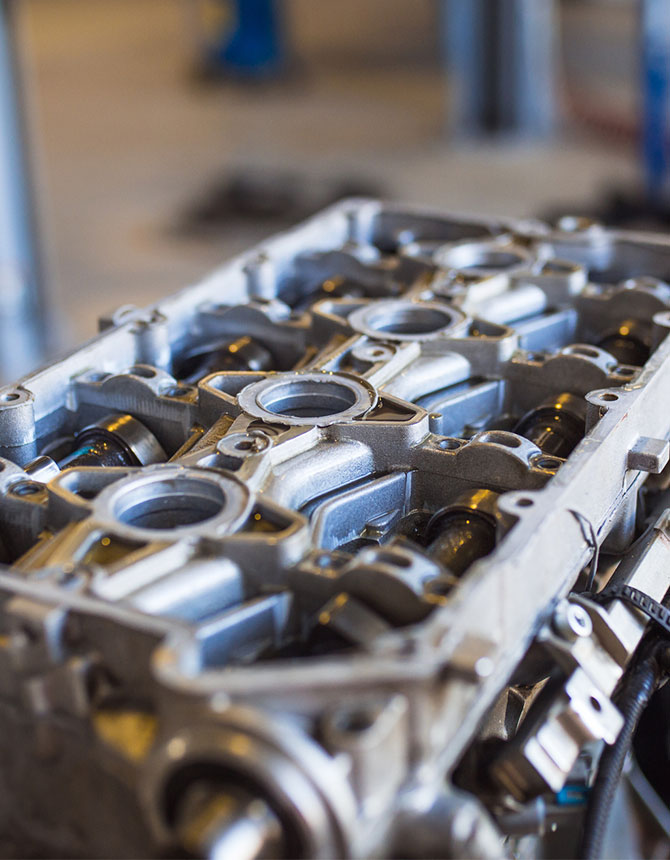

Our Expertise

Learn more about what we do at LSM and our areas of expertise.

Your Manufacturing Partner

To start your next camshaft or critical component project, contact LSM Systems Engineering today. We can help you quickly take your project from concept to production with a deep commitment to your success.